The company involved in this case study is a multi-national manufacturer of wind turbines that meets the needs of alternative energy production worldwide. Despite having the turbines installed in the ideal location, seasonal conditions brought upon a unique set of issues that required technical support to resolve. Total Filtration Services partnered with Permatron to resolve their concerns with a simple but effective filtration solution.

THE CHALLENGE

The customer had installed a base of turbines in areas that are often flat and sparsely inhabited. As it turns out, these optimal conditions often occur in farmlands. In those areas where corn fields are nearby, seasonal conditions can lead to corn pollen entering the turbine compartment and fouling the impeller. This fouling impacts the speed/efficiency of the turbine’s rotational energy leading which in turn, triggers an alarm on that particular unit.

The customer had installed a base of turbines in areas that are often flat and sparsely inhabited. As it turns out, these optimal conditions often occur in farmlands. In those areas where corn fields are nearby, seasonal conditions can lead to corn pollen entering the turbine compartment and fouling the impeller. This fouling impacts the speed/efficiency of the turbine’s rotational energy leading which in turn, triggers an alarm on that particular unit.

THE SOLUTION

The previous solution to this challenge required the owner of that unit to send a technician to the location to clean the unit. This entailed traveling to the often-remote location, climbing the tower to enter the unit, cleaning the foulant and then resetting the alarm. In several cases, during the peak pollination season, this was a daily occurrence.

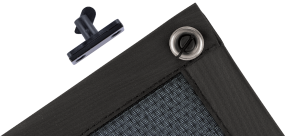

TFS, working with one of its many trusted manufacturing partners, Permatron, proposed the installation of their PreVent system screens at the inlets to their turbine’s impeller enclosures. The PreVent technology incorporates an electrostatically-charged material that enables the attraction/capture of airborne particles much smaller than the mesh size of the screen while having a negligible effect on air flow.

TFS worked with the customer to best identify those locations that might see the best use of these filters and helped to specify the correct size and model of PreVent screen.

THE RESULT

The most obvious benefit discovered by the customer after installation of the PreVent screens was the reduction of alarm events due to seasonal pollen issues. In fact, even those areas with daily alarms saw zero alarms after installation.

The customer experienced not only a reduction in the labor/time spent on addressing these daily occurrences, but increased energy conversion as the pollen no longer impacted the efficiency of the turbines/impellers. As the PreVent screens are washable/reusable, the customer now incorporates these filters on most new installations as a standard practice.

This blog was contributed by the Total Filtration Services Team.