Every service call is an opportunity for contractors to evaluate the customers existing air filtration method and offer a better solution. If the system has a disposable air filter already installed, you can suggest an upgrade to an electrostatic air filter, which is easily washable, eliminates frequent replacements and addresses the environmental concerns of disposable air filters, while improving overall air cleaning.

Every service call is an opportunity for contractors to evaluate the customers existing air filtration method and offer a better solution. If the system has a disposable air filter already installed, you can suggest an upgrade to an electrostatic air filter, which is easily washable, eliminates frequent replacements and addresses the environmental concerns of disposable air filters, while improving overall air cleaning.

The customer may be interested in an electronic air cleaner, but may not be in a position to make the investment in the unit or the requisite system modifications. You do not need to lose this sale if you offer a less expensive but highly efficient electrostatic air filter.

If the customer already has an electronic air cleaner, but complains it emits a popping noise, which is actually electrical arcing, you can suggest replacing the metal mesh prefilter with a ¼ inch thick electrostatic prefilter. This is a permanent, washable and more efficient air filter that can reduce the noise and the cleaning requirements of the unit. The addition of an activated carbon afterfilter will capture the resultant ozone emissions of the unit.

If the customer already has an electronic air cleaner, but complains it emits a popping noise, which is actually electrical arcing, you can suggest replacing the metal mesh prefilter with a ¼ inch thick electrostatic prefilter. This is a permanent, washable and more efficient air filter that can reduce the noise and the cleaning requirements of the unit. The addition of an activated carbon afterfilter will capture the resultant ozone emissions of the unit.

Electrostatic Air Filters – How Do They Work?

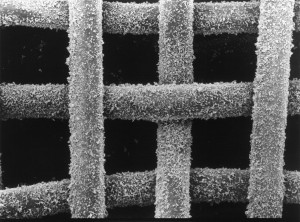

Electrostatic air filters use a combination of charged airborne particulate attraction and impingement action to clean indoor air. The air filter fabric’s inherent electrostatic charge remains constant over time, and enhances filtration by drawing airborne particle onto fiber surfaces, like iron filings onto a magnet. Static electricity, being static, does not flow like electrical current and therefore does not discharge or require either grounding or insulation. Impingement is simply the penetration of airborne particle into and onto the filter media as propelled by airflow.

Electrostatic air filters use a combination of charged airborne particulate attraction and impingement action to clean indoor air. The air filter fabric’s inherent electrostatic charge remains constant over time, and enhances filtration by drawing airborne particle onto fiber surfaces, like iron filings onto a magnet. Static electricity, being static, does not flow like electrical current and therefore does not discharge or require either grounding or insulation. Impingement is simply the penetration of airborne particle into and onto the filter media as propelled by airflow.

Like other air cleaning products, electrostatic air filters are designed to remove the airborne particulates as the indoor air is recirculated through the ventilating system.

Electrostatic Filter – What Is the Advantage?

Particles visible to the naked eye are 50 microns or larger; this size particle will not remain in the air more than a few minutes unless there is a high air velocity moving through the building, keeping the particles up and air borne. In order for air filters to work most effectively, the system’s recirculating fan should be running continuously or at frequent intervals.

When specifying an electrostatic air filter, it is important to keep in mind that not all electrostatic air filters work in every application. Equipment manufacturers are using advanced technology, changing the way they develop HVAC systems to increase benefits and address current energy efficiency concerns.

Many of the components are more sophisticated and, therefore more sensitive to surrounding conditions, including minimal air flow restrictions. This is a key consideration for manufacturers of air filters and the contractors who recommend and install them. If an air filter is installed with a pressure drop that exceeds the equipment manufacturer’s requirements, costly parts such as compressor may be damaged, and the warranty may not be honored.

It is therefore critical that the proper air filter be selected, not simply the one with the highest arrestance efficiency. Excessive pressure drop may be much more expensive in the long run.

Air Filter Sizing

An industry rule of thumb for proper filter sizing is to keep within a certain range of airflow, approximately 2.0 to 2.5 cfm/sq in. of filter surface. For example a 24-by 24-in. filter has approximately 576 sq. in. of filtering surface area.

If you divide the cfm at which a residential system runs (1,200 for example) by the filtering surface area, you have 2.08 cfm/sq in.

This number falls within the rule of thumb for most residential systems. While the filter can handle a lower or higher air flow than is recommended, such variations will have an effect on pressure drop.

In general, the more filtering surface area, the lower pressure drop with constant airflow. To maintain proper airflow as required by the system, the contractor can modify the filter rack to control air flow by filter size, and/or use a filter designed for lower air flow resistance.

Select the Right Size Electrostatic Air Filter

When selecting the proper electrostatic air filter for installation in a given application, it is important to take all parts of the test data as a whole. That is, the highest arrestance does not necessarily mean the most efficient filter, as higher arrestance may mean higher initial resistance to airflow.

Too often, high arrestance is the result of face loading (particulate buildup) and blocked airflow, often spotted by low dust-holding capacity test data. You can determine if a filter as gaining arrestance efficiency by virtue of face loading by evaluating the dust-holding capacity, which may be relatively low in an improperly constructed filter.

Proper construction of electrostatic air filters makes for minimal air flow restrictions.

Uses for Electrostatic Filters

Although commercial electrostatic air filters have been available for almost four decades, their comparatively recent use in residential systems still makes them something of an unknown.

As such, several myths and misconceptions have arisen which should be addressed.

– Air Filter Myth #1 –

Unlike HEPA air cleaners, electrostatic air filters are generally not effective for the removal of submicron-sized particles, such as gases, from indoor air. However, cleaning the air of submicron-size particles is not critical for most residential and commercial applications. The particles that foul the air, trigger allergies, and may cause adverse health effects are much larger in size. Examples include pollen, dust and mold spores.

– Air Filter Myth #2 –

A second misconception is that electrostatic air filters can cause system trouble. Due to their permanent nature, electrostatic filters require no change-outs. Instead, they must be cleaned on a fairly regular basis. Further, if the filter is properly designed, buildup on the front panel (face loading) is minimized in case a regular cleaning schedule is not strictly adhered to. Cleaning simply involves back flushing with water, a job that can easily be built into a service contract. In commercial applications that require multiple air filters, two filters can be purchased. When monthly cleaning occurs, a clean filter set is immediately installed and the dirty set is cleaned at a more convenient time.

– Air Filter Myth #3 –

A third misconception concerns the idea that steel frames can discharge electrostatic media. By definition, static electricity is static. That is, it stays in one place, unlike electrical current that flows through a conductor. Polypropylene media is not a conductor, and static electricity is not a current. It is impossible to ground out the static electric charge of the filter media. Steel frames have significant advantages, including structural strength. This is especially important in a product that is regularly handled for cleaning, and is exposed to a variety of challenges, such as humidity and temperature variations or extremes.

Commercial Electrostatic Air Filters Market

I f you are concentrating on residential sales and service, do not overlook the lucrative commercial market, where electrostatic air filters are often installed in quantity within filters banks. Check with the manufacturer to determine which air filter model is designed for a given application – not all will be appropriate for the system requirements.

f you are concentrating on residential sales and service, do not overlook the lucrative commercial market, where electrostatic air filters are often installed in quantity within filters banks. Check with the manufacturer to determine which air filter model is designed for a given application – not all will be appropriate for the system requirements.

Washable Air Filters Add Value

Electrostatic air filters are a value-added product which give you much to talk about. In addition to the environmental advantages, there are many reasons to choose a washable air filter over a disposable one. Features like: washability, removing air allergy triggers, less house cleaning, no ongoing replacement costs, no system modifications and low resistance to air flow for system protection are all great – but the real advantage of Permatron’s washable air filters is that they are built to last.