TreeHouse Foods is a leading global provider of private label foods and beverages for retail grocery and foodservice. With 26 manufacturing, packaging, and distribution facilities across the United States and Canada, the company boasts uncompromising standards of food safety and quality, underpinned by manufacturing best practices and operational excellence. The company is committed to conducting business in a manner that conserves energy and water, minimizes waste and emissions, and promotes the conservation of natural resources. However, the common dust challenges that arise from processing raw agricultural ingredients in food processing plants create an atmosphere of increased maintenance costs and equipment downtime.

CHALLENGES

One of TreeHouse Foods’ facilities, located in Columbia, SC, has a mill strategically located behind a packaging plant to streamline their production process. As flour is loaded into trucks for transport, the intakes of plant rooftop air handlers – including make-up air units and chillers – are constantly bombarded by clouds of flour dust. Over 175 bag and pleated filters within the make-up air units frequently became clogged with flour dust, requiring multiple maintenance technicians to change them out 4 times a year, and the added expense of crane and dumpster rentals.

SOLUTIONS

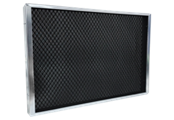

BDI, a global distributor and supply chain company, was called in to find a cost-effective air filtration solution to solve TreeHouse’s airborne flour dust issues. Todd Shearer, a representative from BDI, recognized that the addition of Permatron’s PreVent System prefilter would capture the flour dust before it can get drawn into the outside fresh air intakes and reach the higher efficiency bags and pleats. PreVent is a washable and UV-protected polypropylene air intake filter that is available with a range of frame and mount customization options depending on the application. For this installation, with existing filter bank channels, 1″ thick metal frames and wire reinforcement were used.

RESULTS

TreeHouse saves over $58,000 dollars annually, at this location, in reduced filter replacement and maintenance costs by installing washable electrostatic prefilters. Periodic prefilter cleaning and air flow monitoring has reduced interior filter changeouts to 2X per year.

Designed to capture high dirt loads with easy cleanability, PreVent filters can be quickly rinsed or brushed clean to optimize system air flow for better energy efficiency and equipment life.

TreeHouse expanded their use of PreVent filters on their chillers to reduce coil cleaning. Interior equipment, like recirculating fans, compressors and electronic enclosures would also benefit from these filters to ensure clean processing and smooth production flow critical to quality assurance and a profitable bottom line.

“Proper air filtration is critical in food processing plants to keep the lines running and cooling equipment efficient. PreVent prefilters are a must.”

-Todd Shearer, Sales Manager, BDI