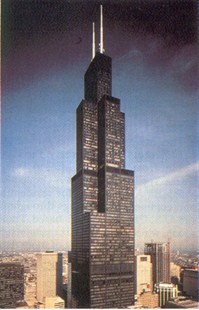

Eliminating flying dirt and nasty weather conditions in the windy city of Chicago could prove to be a major challenge for any HVAC specialist; especially when the outside air intake ducts happen to be located on the 108th floor of the Sears Tower. When Motorola found they were having air intake problems at their two-way radio transmitting station they called in their HVAC experts, Moto HVAC Corporation, the Chicago contractor who maintains their equipment. The two outside air intake ducts were not only battling the high concentration of atmospheric particulates and moisture, but also an air velocity of over 1,000 feet per minute. Motorola had been utilizing two banks of filters; one bank of fiberglass throwaway prefilters, followed by a bank of bag filters. Neither filter was holding up to those extreme conditions. Continuous maintenance added up to high equipment repair and filter replacement costs. Prefilters required replacement approximately every two to four months, at a cost of around $200 plus labor, over $1,000 annually. Bag filters required replacement on a one to two year basis, at a cost of approximately $1,300 plus labor, over $1,600 annually.

Permatron’s Electrostatic Filters

Moto ultimately installed fifteen 24″ x 24″ x 2″ and six 12″ x 24″ x 2″ Model IN permanent electrostatic filters manufactured by Permatron Corporation of Elk Grove Village, IL. The filters Moto installed for Motorola required no modifications to their current air intake ducts, plus the filter’s construction is designed to hold up to both atmospheric conditions and high air flow velocity. Because the filters are permanent, the total installation cost was less than what Motorola was paying annually for bag and throwaway filters. Having made it through a brisk Chicago winter, Motorola administrators are very pleased with the results. Maintenance is limited to periodic water washes of the filters and quarterly maintenance checks by Moto HVAC Corp.