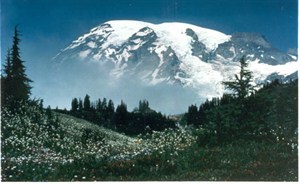

Of the two million visitors to Mount Rainier National Park each year, about three fourths enjoy informative, educational presentations within the audio-visual room of the Henry M. Jackson Memorial Visitor Center at Paradise, located at an elevation of 5,400 feet on the south slope of Mount Rainier. Unfortunately, while enjoying the largest volcano in the magnificent Cascade Mountain Range, eruptions from Mount Rainier and other volcanoes in the Cascades have spread layers of very fine, abrasive volcanic ash over the entire region. Glacier movement, which is continual, grinds the hard rocks of the area into the colloidal size dust that visitors inadvertently track into the exhibitor and auditorium areas of the visitor center. Even in this mountain fresh atmosphere, normal maintenance removes most of the dust on a daily basis, but over the years it had found its way into every nook and cranny of the center. Lint from the carpet, dust from the outdoors and greasy fumes from the cafeteria concessions all find their way into the 10x15x8 foot projection room of the center’s auditorium.

Problem – Dust and Ash

Since 1967, antique film and slide projectors looped to a pair of film trees showed visitors continuous programs which enhanced their park experience. However, the staff member who maintained the setup retired, and the equipment was replaced with sensitive, solid state projection devices. Like many technologically advanced devices, the new projectors required absolute dust free environments to function properly. The solid state message repeaters produce spurious results when dust particles short-circuit connections. The least bit of dust wreaks havoc with the film trees and the video projector shuts down when it clogs with dust. Taped message repeaters sound like sandpaper commercials when dirty. They were losing at least a film or tape every week. The projection room was originally designed to have a negative pressure, and a great volume of particulate matter had accumulated. An ordinary disposable air filter had been installed as a prefilter to the heavy duty exhaust fan which was positioned in the doorway, with negative pressure being run into the room. The furnace filter was expected to eliminate the problem, but was quickly overwhelmed by the volume of contaminants. Even with continual cleaning, the room appeared like a dusty attic.

Solution – PreVent® Air Filters

It was determined that positive pressure should be run instead, thereby pushing dust out of the room, and a cost effective air filtration solution was needed. After a thorough cleaning, the exhaust fan was set up with Permatron’s PreVent® Equipment Protection Filter as a prefilter and afterfilter on either side. A set of washable, hammock-style filters was designed consisting of nonwoven polyester with a layer of woven electrostatic media on either side, bound together with a flexible vinyl edge. A third filter was installed on the existing ceiling vent to prevent entry of contaminants from that source. The flexibility of the vinyl edge accommodated the curved surface of the fan housing, eliminating the need for any system modifications. Independent laboratory tests indicate that these filters offer 87%-96% average arrestance efficiency at 600 to 1200 CFM, high dust holding capacity and low initial air flow resistance. The fan flows freely, but the dust is no longer entering the room, and the positive pressure keeps other dust from entering around the door casings. The filters were so effective at capturing airborne particulate matter in this configuration that within the first week, daily cleaning of the filters was required. Thereafter, weekly cleaning was sufficient, and an average cleaning schedule of twice each month followed. The projectors and message repeaters are humming along; visitors are once again enjoying programs without interruptions. Buildup of dirt impacts equipment’s ability to work efficiently and increases the need for repeated maintenance or equipment replacement. PreVent® the damage before it’s too late!