Out-of-sight, out-of-mind, and a potential nightmare. Equipment enclosures keep your dials and switches and wires away from damage, and keep equipment running efficiently. But while they keep vital technology components functioning and out of harm’s way, enclosures are more than metal frames and doors. To be effective, they also need adequate temperature control and air filtration. Which means without quality air intake filters they can do more harm than good.

Out-of-sight, out-of-mind, and a potential nightmare. Equipment enclosures keep your dials and switches and wires away from damage, and keep equipment running efficiently. But while they keep vital technology components functioning and out of harm’s way, enclosures are more than metal frames and doors. To be effective, they also need adequate temperature control and air filtration. Which means without quality air intake filters they can do more harm than good.

In order to provide optimal protection, equipment enclosures need:

Temperature control. Overheating can not only harm sensitive equipment but reduce their lifespan, and an enclosed metal box is just that: an enclosed metal box. It’s important to harness the ambient air outside equipment enclosures in order to efficiently maintain a constant temperature inside the cabinet. The process heat has to be continuously dissipated from the enclosure, which may require a lot of energy but also needs an adequate venting system.

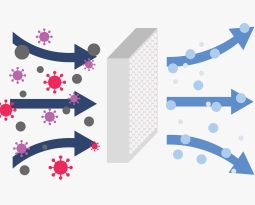

Air Filtration. Just as important as the air temperature is the quality of that air. While vents and fans keep the enclosure from overheating, it also means dirt, grease and other airborne debris can be continually drawn inside the cabinet. Even if the foreign objects are not visible, the buildup of airborne dirt on interior filters and mechanical components will impact the equipment’s ability to work efficiently and require repeated maintenance and cleaning.

The location of equipment enclosures and their air intake vents may also increase the chances of attracting dirt, especially in crowded and heavily populated work environments such as restaurants, laundries, garage/loading docks, manufacturing/ industrial processing areas or remote locations such as bitcoin mining server racks, cell towers and wind turbines. Also, as mentioned earlier, they are often out-of-sight and out-of-mind, and so might only be sporadically cleaned.

The Sofidel Group faced both those problems.

A Solution for Sofidel

The Sofidel Group was founded in 1966 and is a world leader in tissue paper production. Located in the UK, they make toilet paper, kitchen paper and tissues. They use Rittal electrical control enclosures in their factories to house paper processing and conveying controls. As the toilet paper rolls are formed and slit from larger width rolls, they are processed onto cardboard tubes before being conveyed down the line into packaging. Each electrical cabinet has an intake fan and filter unit on the bottom and an exhaust vent on top so that the heat generated by the electronic equipment can escape.

But in their dusty paper environment, the fan filters within their enclosure cabinets clogged up quickly and it was difficult to tell when they were clogged. As a result, changing the interior filter mat was done infrequently and, as they were changed, loose paper fines were immediately sucked into the enclosure. Sofidel Group engineers tried all sorts of workarounds on their enclosures to keep the dust from clogging the interior air filters. The most popular solution was using a pair of women’s tights and insulation tape over the vents. They were time consuming to slip on and, frankly, a little embarrassing.

But in their dusty paper environment, the fan filters within their enclosure cabinets clogged up quickly and it was difficult to tell when they were clogged. As a result, changing the interior filter mat was done infrequently and, as they were changed, loose paper fines were immediately sucked into the enclosure. Sofidel Group engineers tried all sorts of workarounds on their enclosures to keep the dust from clogging the interior air filters. The most popular solution was using a pair of women’s tights and insulation tape over the vents. They were time consuming to slip on and, frankly, a little embarrassing.

The Advantage of Air Intake Filters

Sofidel needed assistance so Dean Hamer, Sofidel’s Automation Engineer, contacted an air filter expert: Richard Betts of RAB Specialist Engineers. Richard recommended Sofidel use Permatron’s PreVent® equipment protection prefilters over their Rittal enclosures. These air intake filters go on the outside of enclosures, over intake openings, for easy access and removal. They keep out the larger contaminants, greatly reducing the need to change interior paper filters. The Model R prefilters are a snap to install, too. Literally. They are held on by strong magnets, powerful enough to stay in place but easy enough to remove and clean. The dirt and dust accumulation is obvious to the eye, so knowing when to clean them is intuitive. The PreVent air intake filters can also be washed quickly and reused indefinitely, even by unskilled labor.

PreVent Model R prefilters are used around the world. These high-flow air intake filters are made with electrostatic woven polypropylene media—dirt, dust and environmental contaminants cling to it like iron filings to a magnet. They are sturdy—encased in rigid steel frames—available in various thicknesses to accommodate applications that can’t be flush mounted to the cabinet because of raised inlet louvers. They can be cleaned with something as simple as a shop vac or a broom.

Well-maintained equipment costs less to operate, ensures optimal life expectancy, minimizes sensitive equipment breakdowns and downtime, and maintains energy efficiencies. That’s exactly what an equipment enclosure with proper air intake filters helps ensure. And in the case of Rittal and the Sofidel Group, just because their equipment enclosures are out-of-sight and out-of-mind no longer means they have to be out-of-pocket with repairing or replacing overheated or dirty equipment.