The costs from a dirty condenser coil go far beyond the inevitable repair bill. Since a building’s heating and cooling systems can account for 70% of its total energy use, the utility costs of a dirty condenser coil can be considerable, as are the costs of replacement for a broken, end-of-its-working life unit.

The costs from a dirty condenser coil go far beyond the inevitable repair bill. Since a building’s heating and cooling systems can account for 70% of its total energy use, the utility costs of a dirty condenser coil can be considerable, as are the costs of replacement for a broken, end-of-its-working life unit.

The Ins and Outs of Condenser Coils

An air conditioner doesn’t produce cold air in the same way a furnace produces heat. An A/C unit uses a refrigerant or coolant to absorb heat and then carry that heat outside. The cool comfort you feel is, in effect, the by-product of effective heat transfer.

That’s why, when Willis Carrier designed the first the AC unit in 1906 he didn’t call his invention an air cooler. He called it an air conditioner. His goal wasn’t to cool the interior of the printing factory where he installed his first system, he wanted to reduce the indoor humidity. But his process to condense humidity from the air also extracted heat energy, and cooling was a very pleasant side effect.

Two of the main components of a cooling system are the evaporator coil, which will pick up the heat, and the condenser coil, that releases the heat outside. The condenser coil performs its part of the job by converting refrigerant vapor to liquid. Once the proper temperature has been reached, and the refrigerant has reached 100% saturated vapor, condensation takes place–changing the vapor to liquid–as more heat is removed. But in order for the condenser coils to perform as intended, with optimal energy efficiency, they need to be kept clean.

Prevent a Dirty Condenser Coil

Even the best HVAC systems won’t deliver ideal performance without proper maintenance. Dirt and dust acts as an insulator, keeping the heat trapped inside, hindering heat transfer. The system will then need to run longer and harder to do its job (if it even can do its job). The temperature coming out of the dirty condenser coil will also be a higher temperature, lowering the net refrigeration effect. The result of all these issues: elevated cooling costs, equipment breakdown and a reduced lifespan for the equipment. Repairs can run in the thousands of dollars, and new equipment can run in the tens of thousands of dollars.

Even a fine layer of dust on the condenser coil reduces its efficiency. As we reported in an earlier article, an EPA study showed that as little as 0.042″ of dirt on condensing coils will cause a 21% drop in efficiency, and can increase refrigeration energy use by 35%. That’s a shocking amount of inefficiency and cost from a relatively minor amount of dirt accumulation.

Keeping the condenser coils running smoothly may also be complicated by their location: outside. Exposed to unfiltered outdoor air, often on the roof of a building, the condenser can accumulate debris including leaves and dirt. These obstacles necessitate frequent cleanings, especially during seasons where debris may be of greater quantities such as cottonwood season.

Coil-Cleaning Checklists

Condensers require regular and often frequent cleaning due to environmental factors like dirt, dust and debris. But due to their rooftop locations, cleaning coils can be difficult. Even getting water on the roof can be a chore considering the gallons upon gallons of high pressure water needed to do the job. Assuming you can hurdle those obstacles, here are the recommended steps you should take when cleaning a dirty condenser coil:

- Shut the system down.

- Make sure there is access to water and power.

- Avoid high pressure cleaning systems that can damage fins. Consider a cleaning system that produces 400 psi at around 3 gal/min in order to flush out dirt and debris.

- Apply noncaustic, nonfuming coil-cleaning chemicals and let them sit for a few minutes to penetrate. Pay close attention to the instructions on the coil cleaner.

- Flush coils with water, working opposite the airflow to push dirt out the way it came in.

- Power the unit back up.

How Air Intake Filters Help

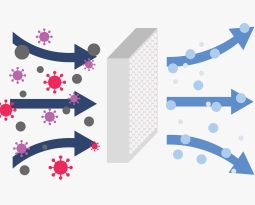

Cleaning is just one of the proactive steps you need to take to keep your equipment running well. Smart building managers know it’s important to install a washable electrostatic air intake filter, such as our powerful PreVent® System Filter Screens.

Our custom-sized PreVent screens protect the coils and can adhere to the outside of metal air intake louvers with powerful earth magnets which require no special tools or training to install. The filters keep debris away, reducing the frequency of cleanings. When dirty they can be brushed off, in place, or easily removed and hosed down, with minimal effort.

A condenser failure is a common and costly result of a dirty condenser coil. But by maintaining them and keeping them clean, the unit should last for years, even decades, with minimal issues. In other words, many of the high costs of a dirty condenser coil can be avoided with the low cost of a quality filter screen.