Sonic Welded Air Filter Frame

Sonic Welded Air Filter Frame

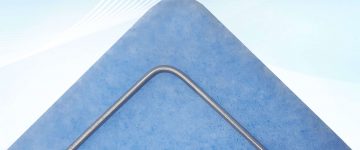

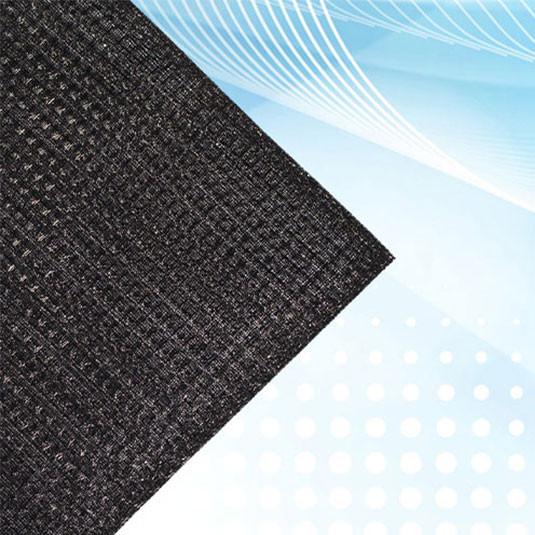

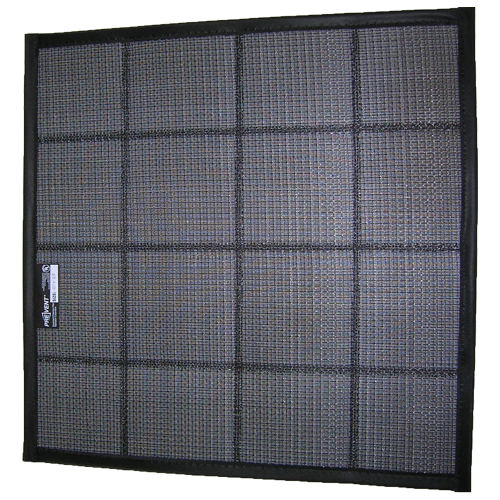

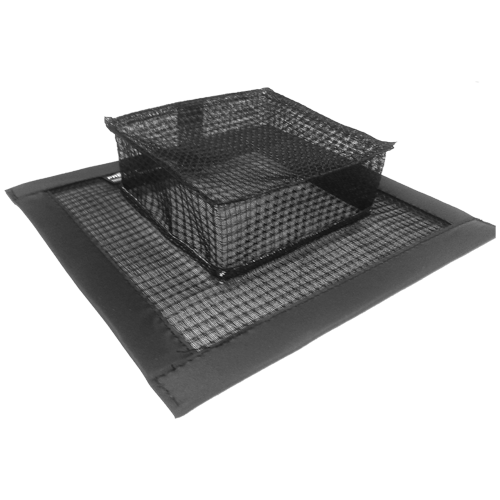

Ultrasonic bonding is a reliable and cost effective filtration assembly solution for finishing the edges of flexible, frameless air filters. The system utilizes ultrasonic vibrations to fuse synthetic and non-woven air filter media, giving the material a nicely finished rigid edge. The bonding process provides a much stronger and dependable bond than is produced with stitching, glue or hot air methods, eliminating frayed or unraveling edges. Bonded edging also eliminates concerns about stitch holes, glue gaps and broken threads. Sonically bonded air filter edging is ideal for custom designs with tight tolerances and curved shapes. Multiple layers of filter media can be easily bonded together and finished, as well as shaping cube, bonnet and bag style filters. A sonic welded grid pattern can be added to keep the filter smooth, flat and space-saving.