For most facility and building managers, their HVAC system isn’t always top of mind … at least until it doesn’t work. Then, it’s hard not to think about it. HVAC repair costs can be considerable—and those costs are just the beginning. Consider also the costs from production downtime in a manufacturing facility; the melting of perishable goods in a grocery store; the corrosion of technology equipment in a data center; sick office workers from poor air quality; or the loss of customers from an uncomfortable retail environment or restaurant. But regular HVAC preventative maintenance, which can include scheduled filter cleaning or change-outs, gasket replacements, airflow measurements and pressure drop tests, can help avoid many of these issues. Here are the top five ways how HVAC preventative maintenance can save you money:

For most facility and building managers, their HVAC system isn’t always top of mind … at least until it doesn’t work. Then, it’s hard not to think about it. HVAC repair costs can be considerable—and those costs are just the beginning. Consider also the costs from production downtime in a manufacturing facility; the melting of perishable goods in a grocery store; the corrosion of technology equipment in a data center; sick office workers from poor air quality; or the loss of customers from an uncomfortable retail environment or restaurant. But regular HVAC preventative maintenance, which can include scheduled filter cleaning or change-outs, gasket replacements, airflow measurements and pressure drop tests, can help avoid many of these issues. Here are the top five ways how HVAC preventative maintenance can save you money:

- You Can Save on Energy

A building’s heating and cooling system can account for 70% of its total energy use, so an inefficient HVAC system can lead to significantly higher energy bills. As you’d expect, the dirtier the coils are, the harder the HVAC system has to work to do its job. In fact, according to the EPA, a buildup of just 1/100th of an inch of dirt or film on an evaporator coil can reduce its efficiency by 5%, and a buildup of .042 (1/20) inches of dirt decreases efficiency by 21%. Fortunately, studies show that HVAC preventative maintenance can make a difference. According to ACHR News, a recent study performed by the San Francisco Department of the Environment, along with the Food Service Technology Center, showed cleaning coils in a rooftop HVAC unit can cut its energy use in half.

- You Can Avoid Repairs

Most commercial HVAC systems are designed to last anywhere between 15 and 20 years. Avoiding repairs is one of the keys to a positive ROI on your HVAC investment, and regular HVAC preventative maintenance is the key to avoiding equipment breakdown. Emergency repairs can easily cost $1,500 or more per unit (depending on size), and that cost of repair increases even more when you factor in lost productivity due to equipment downtime.

- You Can Extend the Life of Your Equipment

The less often you perform HVAC preventative maintenance, the dirtier your equipment becomes. The dirtier your equipment becomes, the harder it has to work. And the harder your equipment has to work, the shorter its lifespan. New HVAC units can easily cost tens of thousands of dollars, and these costs are multiplied with additional units. But the cost of the actual unit is just the start. We know of one building that had to replace three rooftop units, and to get new units on the roof they had to hoist them by helicopter. It was a logistical challenge that required FAA flight plans, local government approval, blocking the street—and a cool $20,000. The relative low cost of regular HVAC preventative maintenance more than pays for itself.

- You Can Increase Productivity

There is a very real human cost to dirty and inefficient HVAC equipment. As we wrote in an earlier post, most Americans spend up to 90% of their time indoors, with much of that time spent in office or commercial buildings. Poor ventilation from impaired airflow increases the risk of bacteria growth, mold and Sick Building Syndrome–SBS is one of the main causes of absence from work, and the low efficiency of staff and employees. Even if an employee doesn’t get sick, poor HVAC air flow can impact performance. Many studies have directly tied indoor pollutants with one’s ability to focus. But better air quality equals better health. Per one study published by Occupational and Environmental Medicine: “sick building syndrome decreased by 40% to 50% after workers were transferred to a building with an improved ventilation system.”

- You Can Protect Your Equipment

Dirty air means dirty equipment—not just dirty HVAC equipment, but all the computers and other high tech machinery in your building. With polluted air, machines have to work harder and can break down faster. In areas with higher pollution levels, contaminants can even cause corrosion on circuitry including circuit boards, as well as in solder joints and conductive passageways.

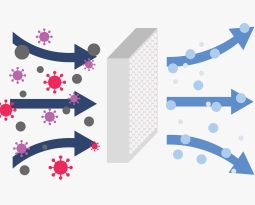

Make HVAC Preventative Maintenance Easier With PreVent®

HVAC preventative maintenance is easier with the help of a washable electrostatic air intake filter such as our powerful PreVent® System Filter Screens. PreVent screens protect HVAC coils by keeping debris and contaminants out, reducing the need to clean them as frequently. When your PreVent screens are dirty, they can be brushed off in place, or easily removed and hosed down. Our PreVent filter screens are secured with powerful MagnaMount® earth magnets, and can be installed in minutes without any drilling. One premier beverage manufacturing company cut HVAC cleaning and maintenance costs by two-thirds after installing the PreVent system! Ensure your HVAC preventative maintenance plan is set, and made easier, with PreVent.