Commercial buildings, schools, hospitals, steel mills, food processing plants, laboratories, print shops, salons, and homes. What do all these places have in common? They all use air filters! It’s safe to assume that most commercial buildings and houses all around the world rely on air filters to help people breathe easier indoors. But how effective is it for the environment?

Commercial buildings, schools, hospitals, steel mills, food processing plants, laboratories, print shops, salons, and homes. What do all these places have in common? They all use air filters! It’s safe to assume that most commercial buildings and houses all around the world rely on air filters to help people breathe easier indoors. But how effective is it for the environment?

What’s bad for the environment?

Thousands of disposable air filters are sent off to landfills every year and they take years to breakdown! Almost all disposable air filters are made out of a combination of cotton paper and polyester. Paper in landfills can take anywhere between 5 to 15 years to break down. Polyester is not bio-degradable and will persist in the eco-system even as it eventually breaks apart. Both materials release dangerous gasses and chemicals as it degrades into the air we breathe. Then we need more disposable air filters to clean up those airborne chemicals… it’s a vicious cycle.

A Green Solution

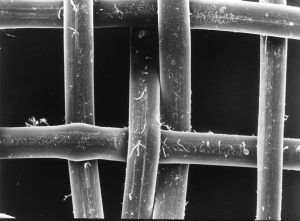

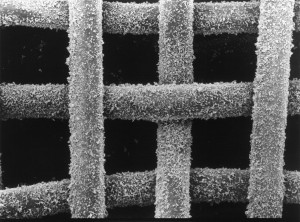

Permatron’s washable and reusable air filters are a better and greener alternative to disposable air filters, to enhance indoor air quality. Our secret? Woven electrostatic media and steel frames.

Electrostatic Air Filters – How Do They Work?

Electrostatic Air Filters – How Do They Work?

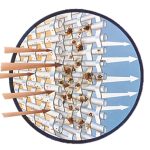

Electrostatic air filters use a combination of charged airborne particulate attraction and impingement action to clean indoor air. The air filter fabric’s inherent electrostatic charge remains constant over time and enhances filtration by drawing airborne particle onto fiber surfaces, like iron filings onto a magnet. Static electricity, being static, does not flow like an electrical current and therefore does not discharge or require either grounding or insulation. Impingement is simply the penetration of airborne particle into and onto the filter media as propelled by airflow.

Like other air cleaning products, electrostatic air filters are designed to remove the airborne particulates as the indoor air is recirculated through the ventilating system.

Electrostatic Filter – What Is the Advantage?

Particles visible to the naked eye are 50 microns or larger; this size particle will not remain in the air more than a few minutes unless there is a high air velocity moving through the building, keeping the particles up and airborne. In order for air filters to work most effectively, the system’s recirculating fan should be running continuously or at frequent intervals.

When specifying an electrostatic air filter, it is important to keep in mind that not all electrostatic air filters work in every application. Equipment manufacturers are using advanced technology, changing the way they develop HVAC systems to increase benefits and address current energy efficiency concerns.

Uses for Electrostatic Filters

Although washable commercial electrostatic air filters have been available for almost six decades, their use in residential systems is still something of an unknown.

As such, several myths and misconceptions have arisen which should be addressed.

- Air Filter Myth #1

- Unlike HEPA air cleaners, electrostatic air filters are generally not effective for the removal of submicron-sized particles, such as gases, from indoor air. However, cleaning the air of submicron-size particles is not critical for most residential and commercial applications. The particles that foul the air, trigger allergies, and may cause adverse health effects are much larger in size. Examples include pollen, dust and mold spores.

- Air Filter Myth #2

- A second misconception is that electrostatic air filters can cause system trouble. Due to their permanent nature, electrostatic filters require no change-outs. Instead, they must be cleaned on a fairly regular basis; monthly is a good practice. Further, if the filter is properly designed, buildup on the front panel (commonly referred to as face loading) and air flow restriction are minimized in case a regular cleaning schedule is not strictly adhered to. Cleaning simply involves backflushing with water. In commercial applications that require multiple air filters, two sets of filters can be purchased. When monthly cleaning occurs, a clean filter set is immediately installed and the dirty set is cleaned at a more convenient time.

- Air Filter Myth #3

- A third misconception concerns the idea that steel frames can discharge electrostatic media. By definition, static electricity is static. That is, it stays in one place, unlike electrical current that flows through a conductor. Polypropylene media is not a conductor, and static electricity is not a current. It is impossible to ground out the static electric charge of the filter media. Steel frames have significant advantages, including structural strength. This is especially important in a product that is regularly handled for cleaning, and is exposed to a variety of challenges, such as humidity and temperature variations or extremes.

Air Filters Custom and Standard

The first washable electrostatic air filters were designed by Permatron for use in high dirt load environments and equipment protection prefilter screens for use on commercial/industrial systems. Similar products, like our DustEater® line, were designed for residential HVAC use. Since then, we have launched the PreVent® System, HailStop®, mist eliminators, bonnets and fan shrouds for air intake protection. Permatron produces widely used industry standard air filters of metal mesh, polypropylene and a variety of other synthetic media including activated carbon for odor and fume removal.

Today, the widespread awareness of indoor air quality and the need for preventative equipment maintenance and GREEN energy efficient efforts presents exciting opportunities in the air filtration industry. No matter the product, Permatron delivers customer focused commitment to quality and service that sets the standard in air filter manufacturing.

Sources: https://greenliving.lovetoknow.com/Environmental_Problems:_Landfills