An American company specializing in building data centers and a leader in global colocation data center market share called upon Total Filtration Services (TFS) to address collapsing filters in their evaporative cooling units at one of their California locations.

THE CHALLENGE

Data centers operate 24/7 with zero tolerance for service interruption and depend heavily on an energy efficient cooling system to prevent servers from overheating. The building involved in this case study uses heat exchangers that are cooled by evaporative cooling systems. The evaporative cooling units use four-inch MERV 8 pleats to filter the air before the air passes the humidification media. The pleated filters were getting blinded-off by significant amounts of large particulate loading onto the media, causing excessive pressure-drop, leading to the eventual filter collapse. As filter media becomes loaded with particulate and airflow is restricted, fan speed for the evaporative cooling units needs to be increased. In addition to an energy efficiency issue, the pleated filters being used were not rated to withstand the additional static pressure, which increased filter collapse risk. If the filters in one of the cooling units collapses, that unit is shut-down, which causes the other units to work harder to maintain the ideal temperature needed to keep the servers cool. This is particularly concerning should the unit go down during the day while outside temperatures are running high. Service at a Data Center cannot be interrupted, regardless of surrounding conditions.

from overheating. The building involved in this case study uses heat exchangers that are cooled by evaporative cooling systems. The evaporative cooling units use four-inch MERV 8 pleats to filter the air before the air passes the humidification media. The pleated filters were getting blinded-off by significant amounts of large particulate loading onto the media, causing excessive pressure-drop, leading to the eventual filter collapse. As filter media becomes loaded with particulate and airflow is restricted, fan speed for the evaporative cooling units needs to be increased. In addition to an energy efficiency issue, the pleated filters being used were not rated to withstand the additional static pressure, which increased filter collapse risk. If the filters in one of the cooling units collapses, that unit is shut-down, which causes the other units to work harder to maintain the ideal temperature needed to keep the servers cool. This is particularly concerning should the unit go down during the day while outside temperatures are running high. Service at a Data Center cannot be interrupted, regardless of surrounding conditions.

THE SOLUTION

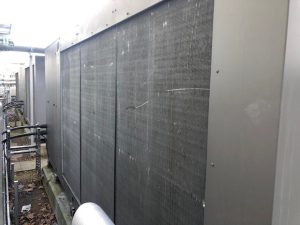

A TFS Account Manager met with the Site Engineer to discuss the filter collapse issue and recommended mounting PreVent air intake filter screens to the outside of the cooling units to prevent the larger particulates from reaching the pleated filters and system coils. PreVent air intake filter screens are custom-made in the USA by Permatron, a long-time trusted partner to TFS. These screens are designed to fit any outdoor air intake, and can be simply brushed or hosed clean, with zero downtime. The customer purchased enough PreVent screens for two of the evaporative cooling units to run a short trial and ensure they would provide the needed protection to prevent pleats from collapsing without excessive energy consumption. TFS worked with the Site Engineer to measure the units and make sure grommets were placed correctly so the screen could be easily mounted to the units. For customers preferring to avoid directly mounting screens to equipment, Permatron also offers an alternative solution with their secure and patented MagnaMount® earth magnets, which take minutes to install, without drilling or tools.

of the cooling units to prevent the larger particulates from reaching the pleated filters and system coils. PreVent air intake filter screens are custom-made in the USA by Permatron, a long-time trusted partner to TFS. These screens are designed to fit any outdoor air intake, and can be simply brushed or hosed clean, with zero downtime. The customer purchased enough PreVent screens for two of the evaporative cooling units to run a short trial and ensure they would provide the needed protection to prevent pleats from collapsing without excessive energy consumption. TFS worked with the Site Engineer to measure the units and make sure grommets were placed correctly so the screen could be easily mounted to the units. For customers preferring to avoid directly mounting screens to equipment, Permatron also offers an alternative solution with their secure and patented MagnaMount® earth magnets, which take minutes to install, without drilling or tools.

THE RESULT

The PreVent air intake filter screens successfully protected both cooling units and prevented the pleated air filters from collapsing. Upon confirming their effectiveness, the customer moved forward with purchasing enough PreVent screens to protect all 14 of the evaporative cooling units for the data center facility. Since outfitting each unit with the protective screens, the Site Engineer for this facility has reported the following improvements:

- The cooling system is more durable and reliable because it is operating efficiently without unscheduled disturbances.

- Increased focus on preventative maintenance as opposed to unscheduled maintenance. PreVent screens can be efficiently cleaned and re-applied in half the time as compared to replacing an unscheduled collapsed filter, which requires shutting down the unit, getting the replacement filters from another building, changing them out, and discarding the collapsed filters.

- Increased energy efficiency due to the cooling system not having to work harder to account for down units. Additionally, the airflow restriction of the PreVent is negligible, which is a common concern for any customer considering equipment protection

- Product costs have been reduced. Because the pleated filters are meeting their life expectancy, replacement pleats are ordered only to maintain the quarterly change-out schedule. This eliminates the need to purchase additional stock for emergencies.

- Disposal costs have been reduced as a result of producing less waste from the excessive replacement of collapsed filters. This reduction has also reduced their carbon footprint.

- The cooling system is more robust and reliable.

- Labor is being used more efficiently.

This blog was contributed by the Total Filtration Services Team.